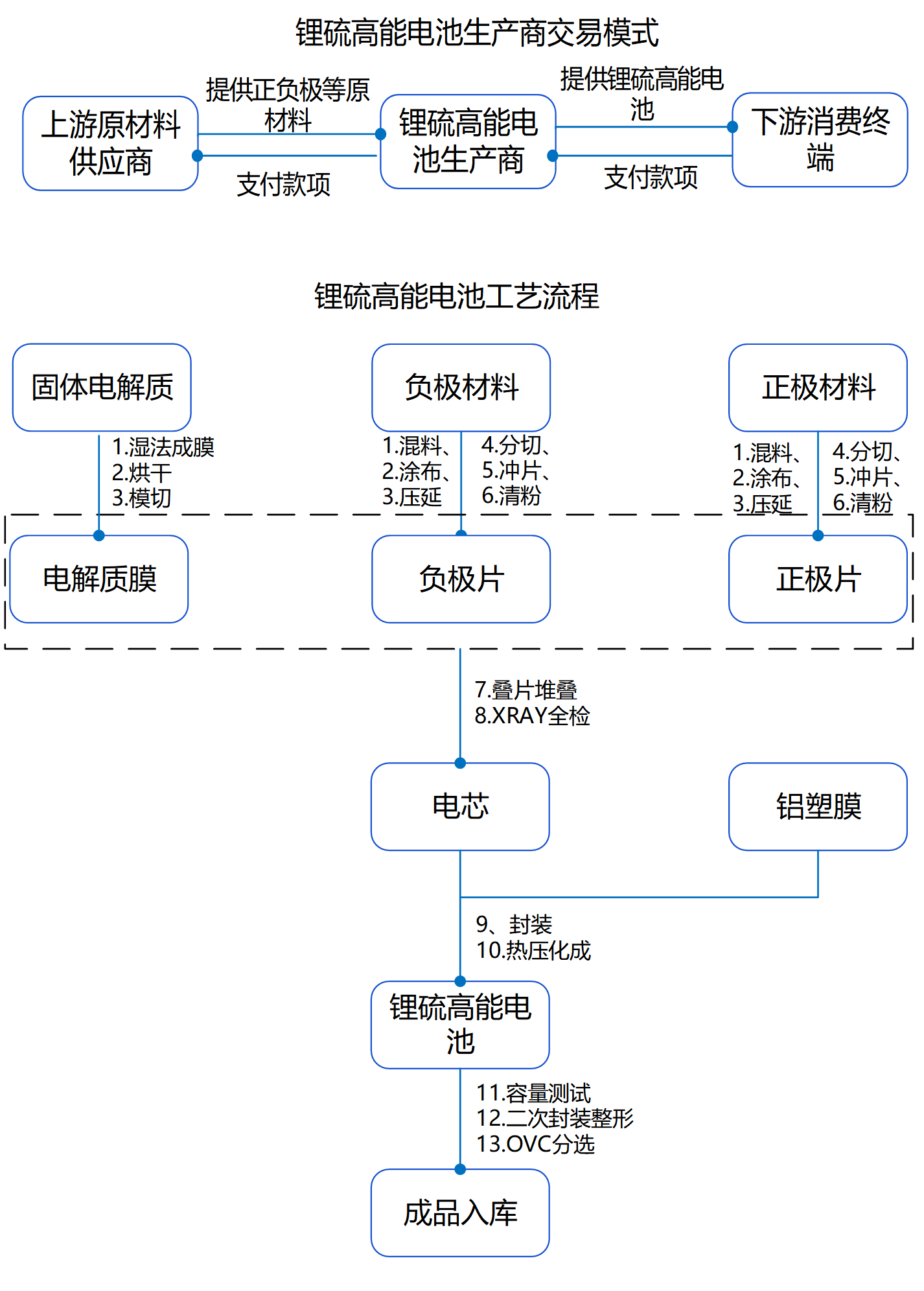

《Made in China 2025》 this book puts forward the battery technology target is 2020, 2025, respectively, up to 300Wh/kg, 400Wh/kg; while the Chinese Academy of Sciences Research Institute Wu Jiao Yang and other statistics show that 1991-2015 energy density has been improved 3 times, according to linear projection 2020, 2025 energy density can only reach 300Wh /At present, these mainstream products are close to the energy density ceiling. Solid-state batteries can achieve higher energy density, volumetric energy density can be more than 1000Wh / L, mass energy density can be more than 400Wh / kg, far beyond the traditional power battery. Solid-state batteries include higher energy density of positive and negative materials and solid-state electrolyte, the current solid-state battery industry, the mainstream technology path has three, respectively: polymer, sulfide, and oxide. Polymer: is the earliest realization of vehicle testing. Advantage is easy to process, and traditional lithium battery production equipment, process compatibility, the disadvantage is the conductivity is too low and lithium metal stability is poor, can not be adapted to high-voltage cathode materials, so limit the energy density. Sulfide is the highest conductivity of the three materials, and electrochemical stability window is wider, but the thermodynamic stability is poorer, in the production level, sulfide solid state battery preparation process is more complex. Oxide has better electrical conductivity and stability, but relative to sulfide, the conductivity is still low, which makes the performance in the performance will encounter a series of problems such as capacity, multiplicity performance limitations, etc. According to the forecast of SNEresearch, the global market size of the solid state battery market in 2022 will be about to reach about $27.5 million, and will form a $40 billion market size in 2030, CAGR of 180%.