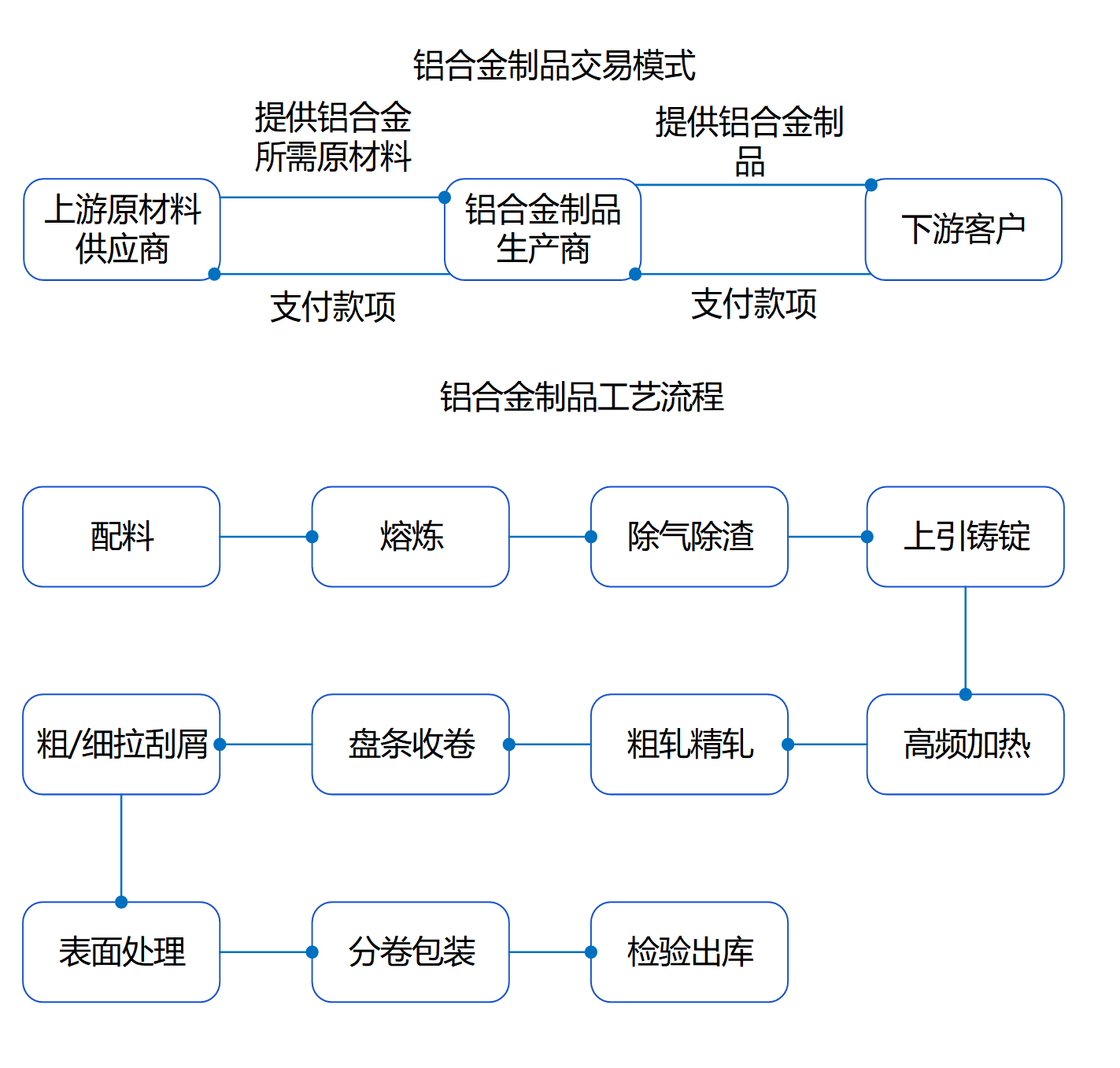

Welding wire is used as a filler metal or at the same time as an electrically conductive wire welding material. In gas welding and tungsten gas shielded arc welding, wire used as filler metal; in submerged arc welding, electroslag welding and other fusion pole gas shielded arc welding, wire is both filler metal, while the wire is also a conductive electrode. Aluminum alloy welding wire as a kind of welding wire mainly includes the following categories: pure aluminum wire, aluminum-silicon alloy wire, aluminum-magnesium alloy wire, aluminum-lithium alloy wire, aluminum-copper alloy wire, rare earth magnesium-silicon iron alloy. Pure aluminum welding wire has excellent corrosion resistance, high thermal and electrical conductivity, excellent processability, mainly used in electrolytic aluminum production, railroad locomotives, electric power, chemical, food and other industries. Aluminum silicon wire has a low melting point and good mobility, low sensitivity to thermal cracking, mainly used in welding or surfacing light alloy processing industry. Aluminum-magnesium alloy is a widely used general-purpose welding consumables. It has high strength, good malleability and good corrosion resistance. It is mainly used in the welding of bicycles, aluminum scooters, locomotive carriages, chemical pressure vessels, military production, shipbuilding, aviation and other industries. Aluminum lithium welding wire is a new type of aluminum alloy welding material with good strong plasticity comprehensive performance. Containing a trace of lithium A1-Mg alloy can be obtained in a wide range of temperature and strain rate range of superplasticity, the maximum elongation of up to 369%. Mainly used in aviation, aerospace welding load-bearing components, such as: fuel storage tanks, warhead shells, instrumentation compartments, the end of the cabin TIG welding, aluminum-copper alloy wire is suitable for welding 2219 and other equivalent grades of aluminum alloy materials, used in the nuclear industry, shipbuilding, aerospace industry, military equipment and other industries. At present, the annual production capacity of high-end aluminum alloy wire is only 40,000 tons, and some high-end aluminum alloys need to be imported from abroad.