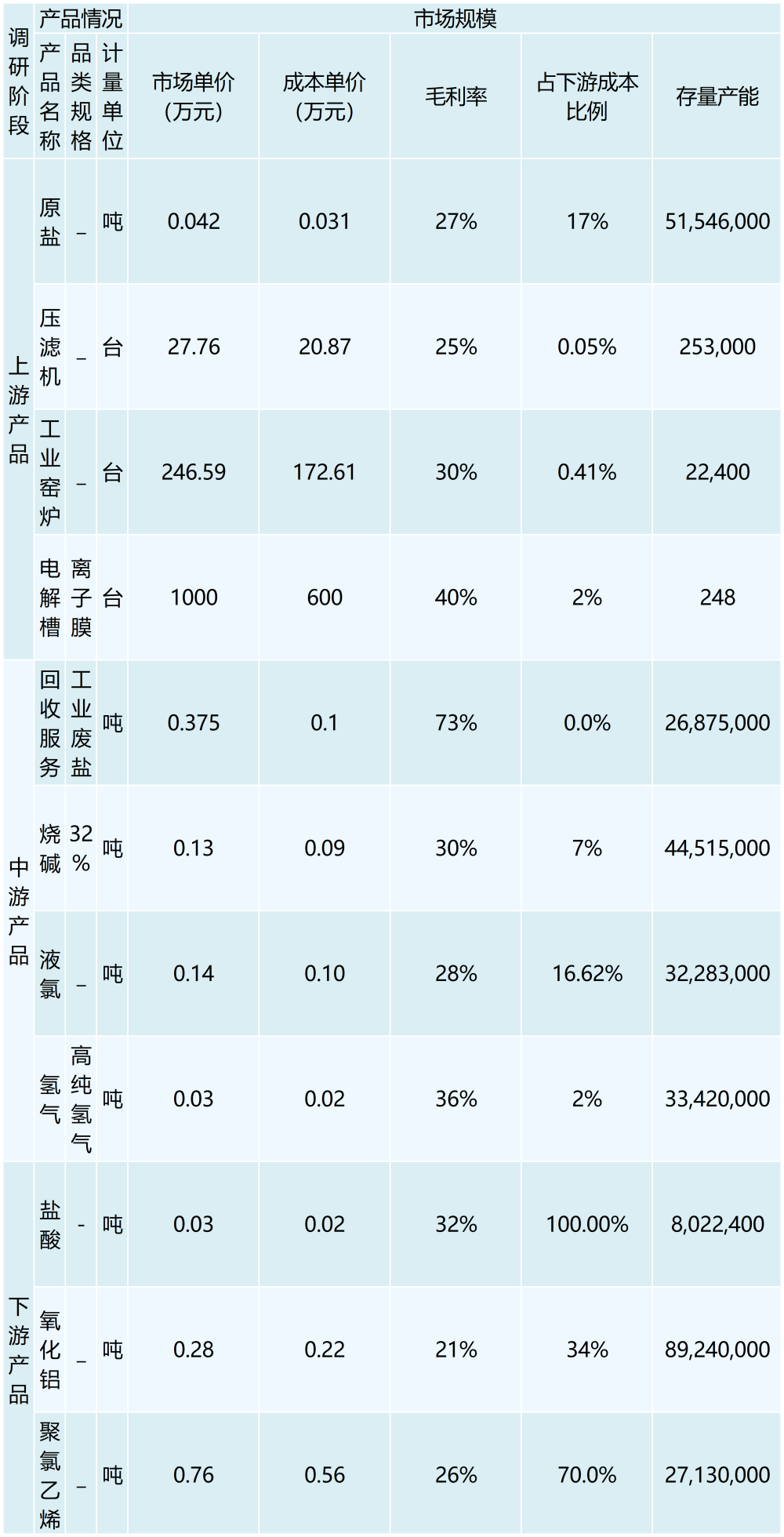

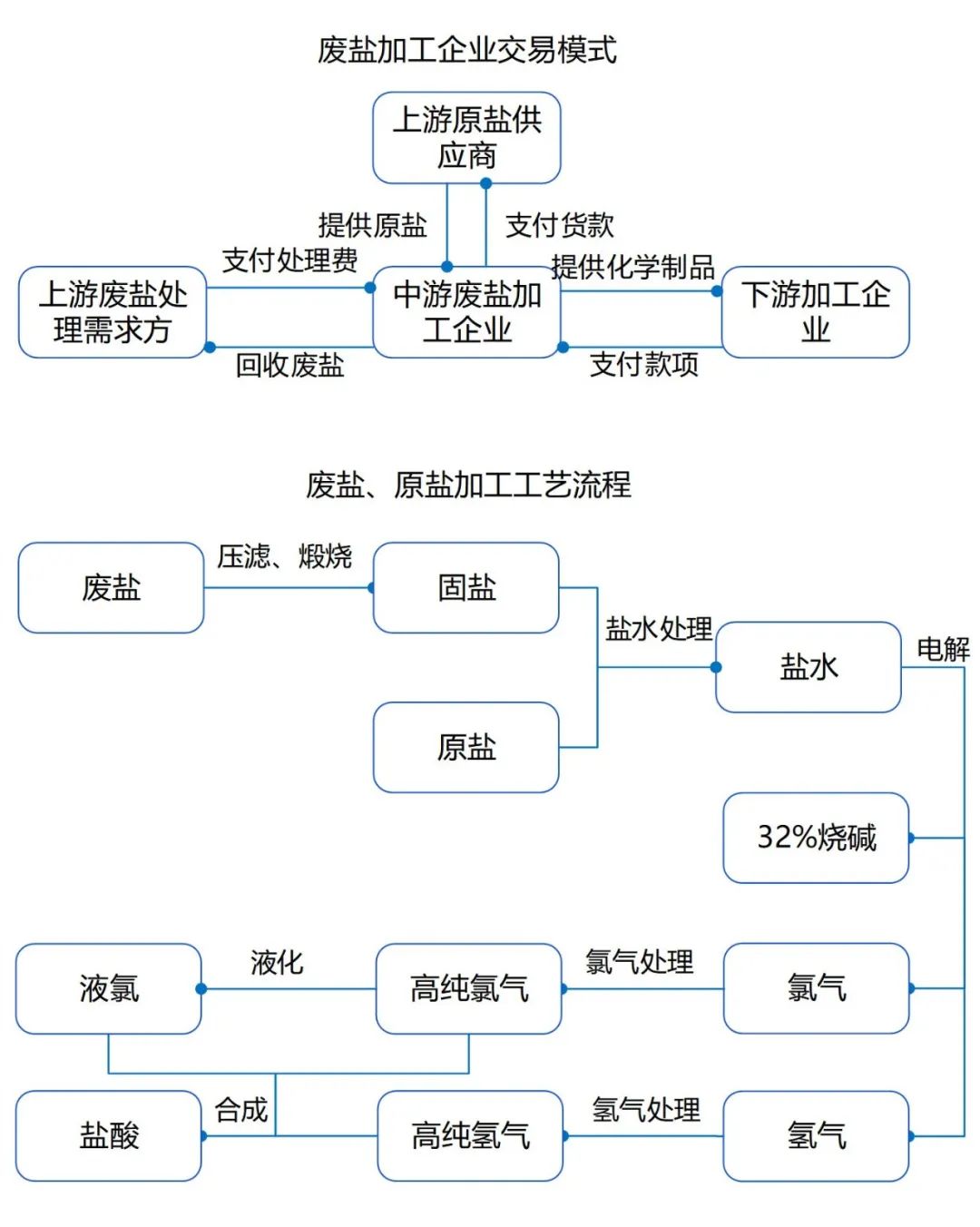

Industrial waste salt refers to the solid waste discharged from the industrial production process with inorganic salt as the main component, the crystallized salt contains a large number of organic or inorganic impurities, which can not be used as industrial raw material salt, such as long-term stockpiling will occupy a large number of sites. In addition, industrial waste salt has complex composition, toxicity and other characteristics, ranked in the “national hazardous waste list”, industrial waste salt will not only damage the ecological environment will also be a scourge of human and animal life, the surrounding agriculture, forestry, animal husbandry, and even the surrounding water sources and groundwater will cause great harm. 2021, China's annual output of industrial waste salt is about 26,875,000 tons, the current market mainstream of the waste salt treatment method to incineration, landfill-based method, but because of the toxicity of waste salt, it can not be used as industrial raw material salt, such as long-term stockpiling will occupy a large number of sites. However, the toxicity of waste salt will cause great danger to the surrounding environment. The new waste salt electrolytic treatment technology perfectly solves this problem, which effectively realizes the secondary use of waste salt by processing waste salt into caustic soda, liquid chlorine, hydrogen, hydrochloric acid and other products. However, due to the limitations of the equipment process, the Chinese market is currently engaged in the waste salt recycling services of fewer enterprises, with the development of advanced technology and waste salt treatment technology is more and more mature, according to the current market recycling of waste salt service fee of about 3,750 yuan per ton projected that the future of China's waste salt recycling services is expected to have more than 100 billion yuan of the market size.