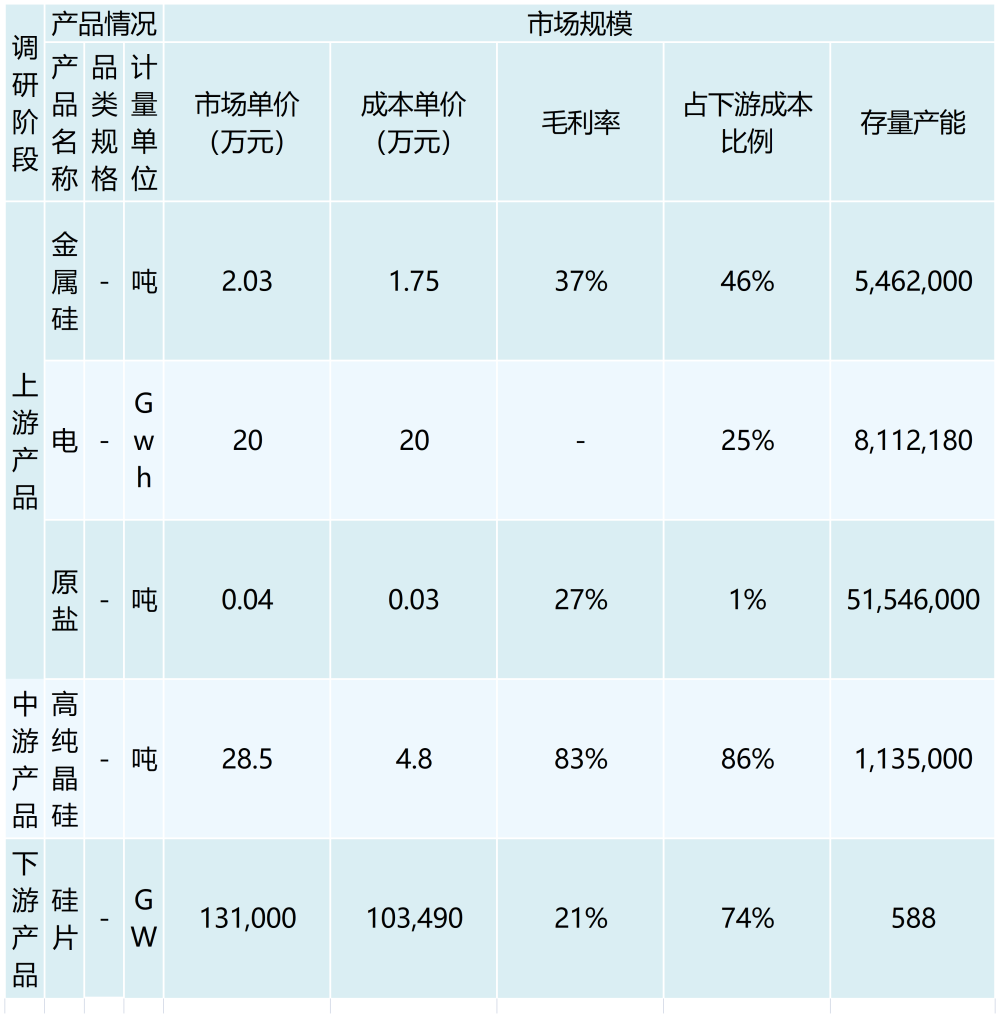

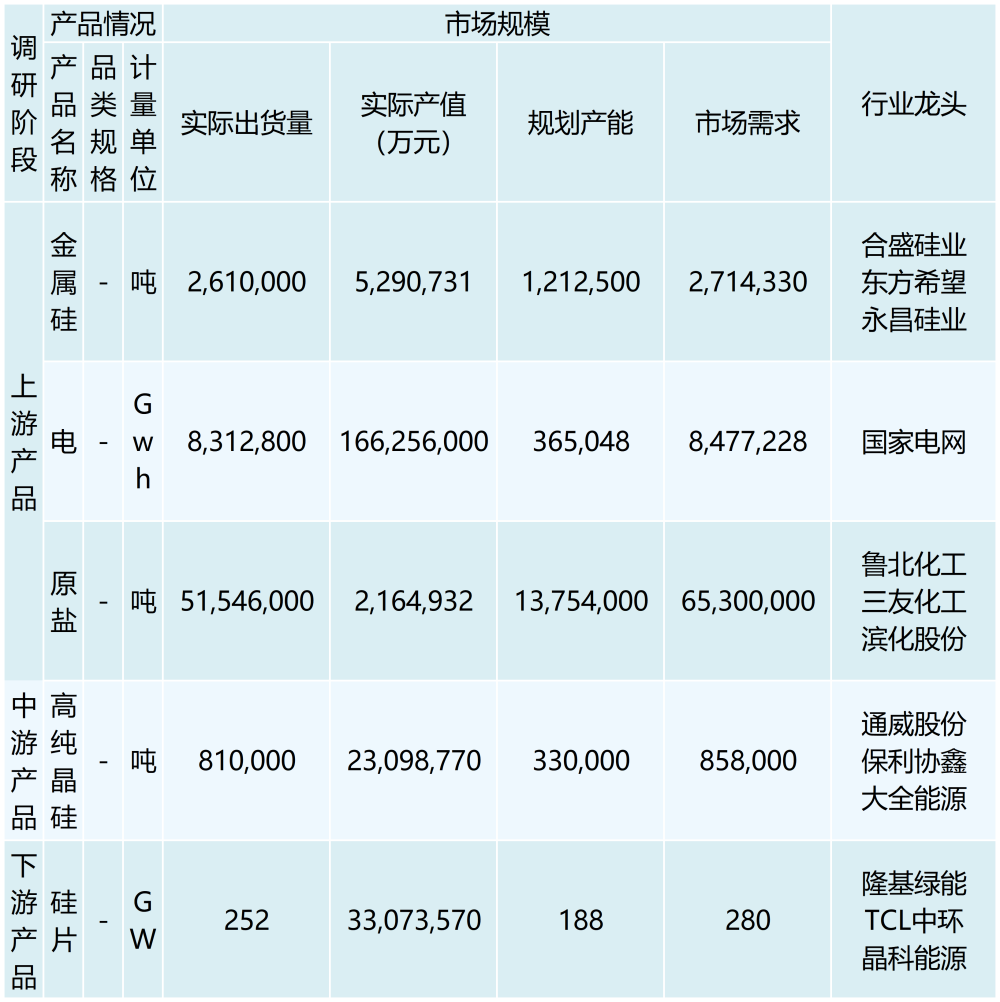

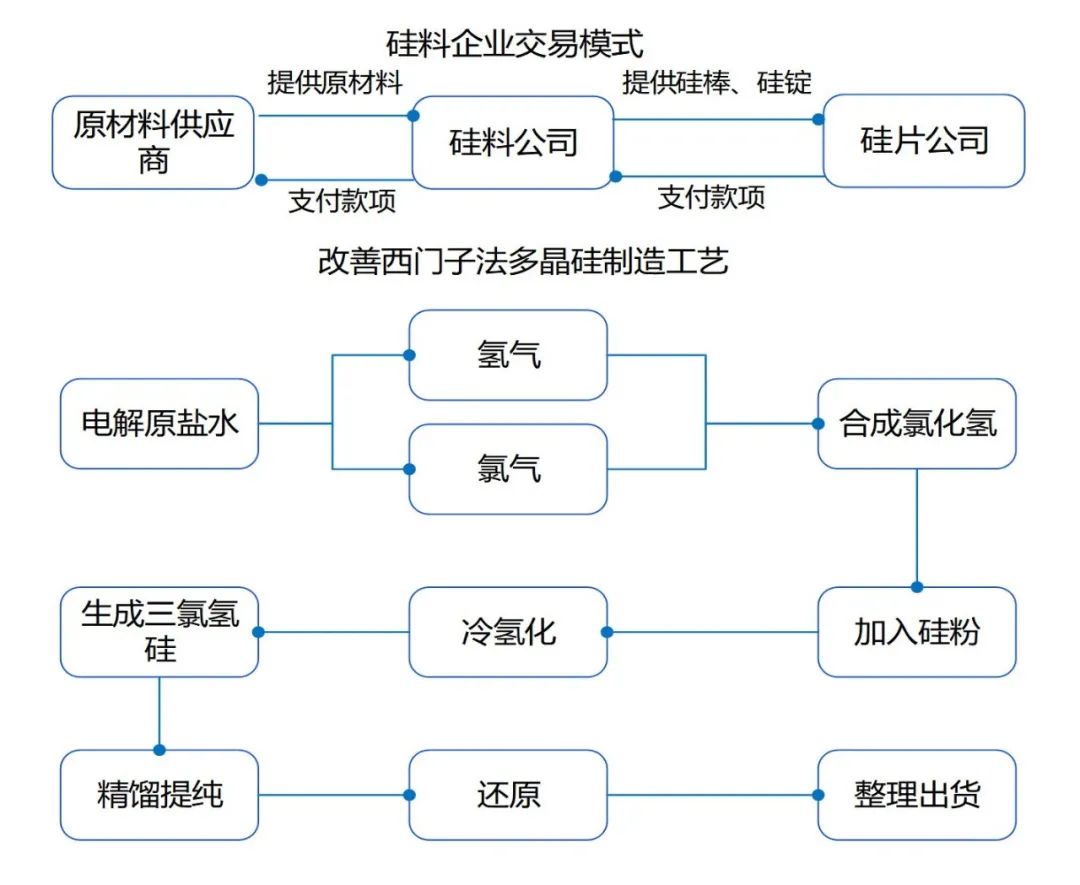

Silicon industry is in the most upstream of the whole PV industry, and the silicon wafers made from silicon processing are the main components for making PV panels and modules. As the cost of photovoltaic power generation continues to decline, the economy drives the new installed demand to gradually increase, in the upstream of the photovoltaic industry chain of silicon material synchronization gains. As the silicon industry expansion cycle is longer than other segments, there is a mismatch between the installed demand for PV. According to the calculation, in 2022 the global photovoltaic silicon market space will reach 946,400 tons, the output of about 919,000 tons, the annual supply and demand for silicon is in a tight balance, 2022 downstream enterprises lock silicon long single volume has reached 743,000 tons, and silicon industry branch predicted that China's silicon production of 810,000 tons in 2022 compared to the silicon industry branch has been locked in the whole year 92% of the output of the silicon material, the silicon material industry has been in a high boom. At present, the improvement of Siemens method is the current mainstream process in the industry, corresponding to the polysilicon market rod silicon accounted for 95.7%, occupying a dominant position. The fluidized bed method with lower process cost is also improving, and the manufactured granular silicon is more cost-effective. Silicon industry will further transfer profits to the downstream to stimulate the development of the entire photovoltaic industry.