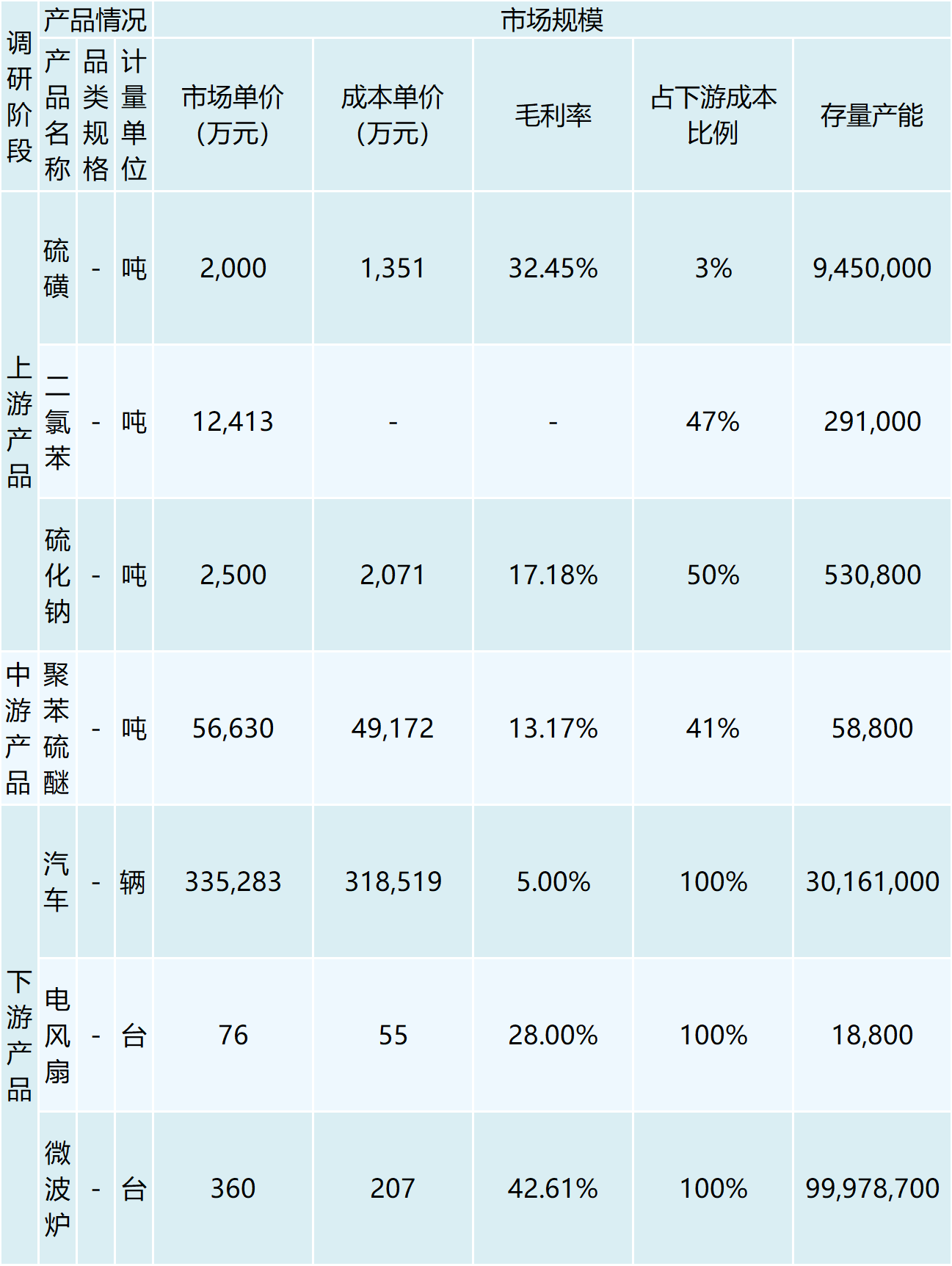

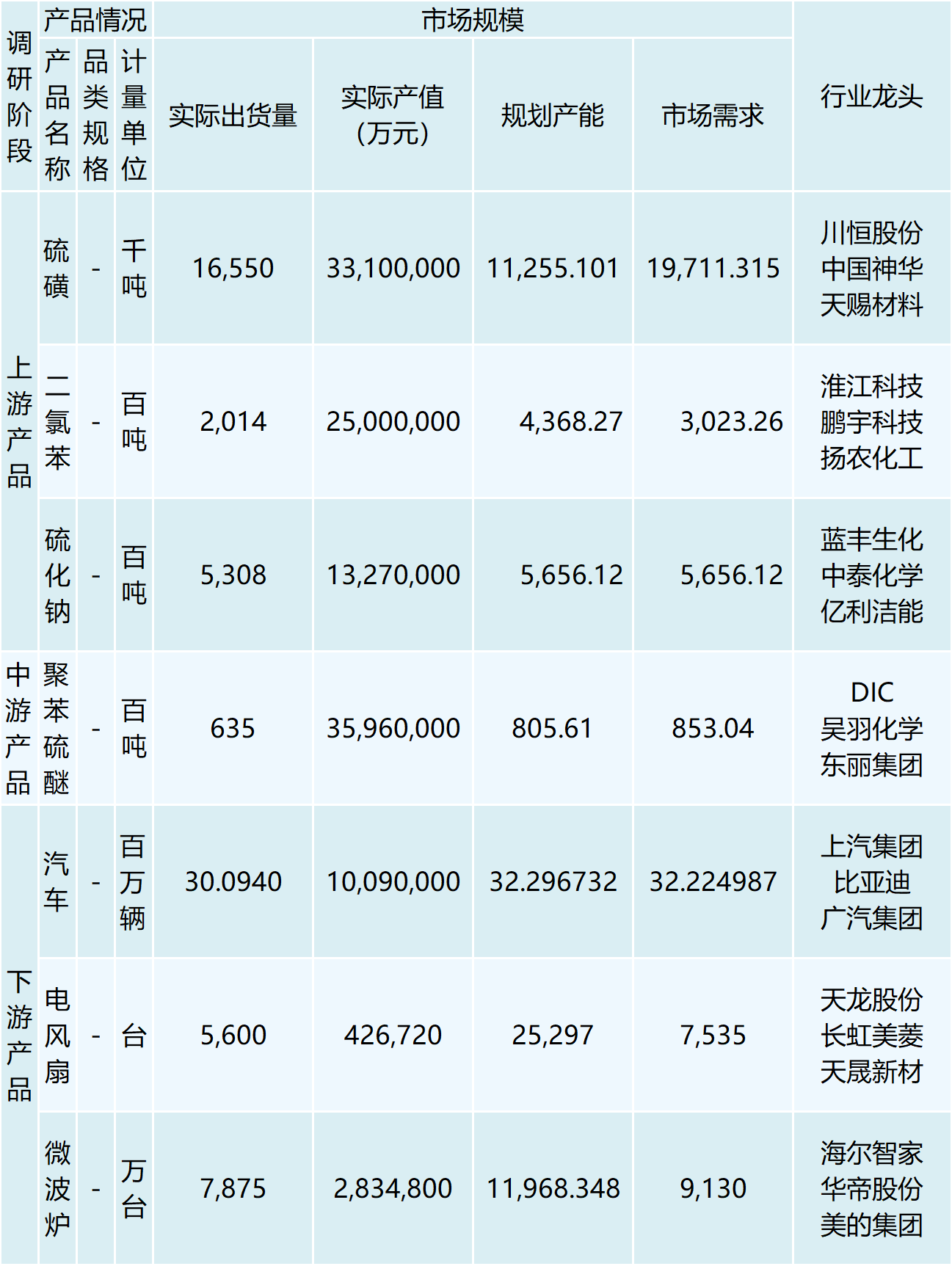

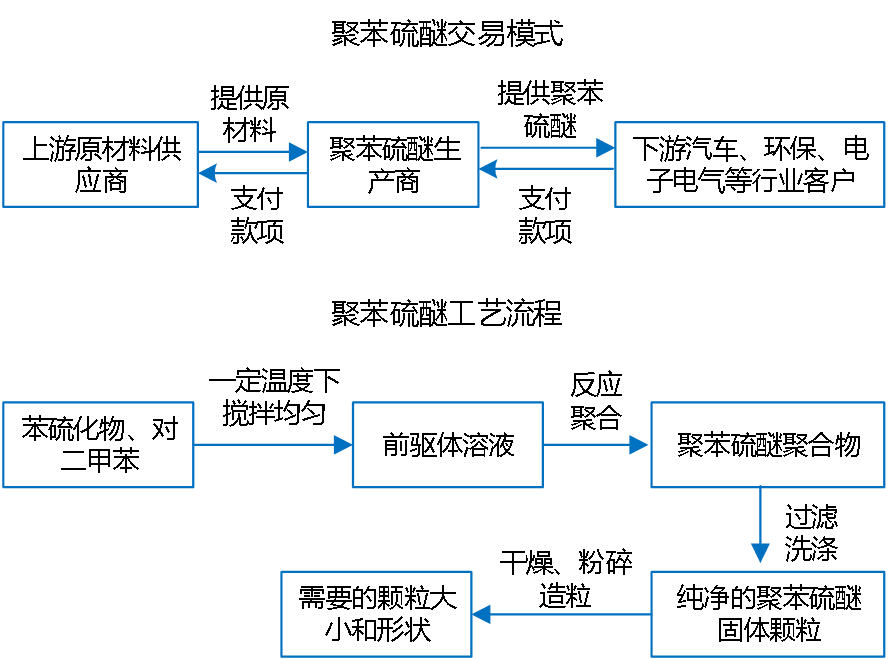

Polyphenylene sulfide (PPS), as a new type of high-performance thermoplastic resin, is widely used in many industrial fields due to its excellent performance. With the continuous upgrading and technological progress of the global manufacturing industry, the demand for PPS materials is also growing, thus promoting the rapid development of the PPS industry chain.The PPS industry chain mainly consists of three links: upstream raw material production, midstream PPS resin manufacturing and downstream application fields. Upstream raw materials mainly include benzene, sulfur and other basic chemical raw materials; midstream PPS resin manufacturing is through the polymerization reaction and other processes to convert raw materials into PPS resin; downstream applications cover electrical and electronic, automotive, aerospace, environmental protection and other industries.PPS resin manufacturing is the core link in the PPS industry chain.PPS resin production process includes polymerization reaction, heat treatment, molding and other steps. PPS resin production process includes polymerization reaction, heat treatment, molding and other steps. During the manufacturing process, the temperature, pressure and other process parameters need to be strictly controlled to ensure the stable performance of PPS resin. According to market data as of the end of 2022, China's PPS market production scale is close to 100,000 tons/year, the production is about 50,000-60,000 tons, imported more than 120,000 tons, no exports, which is calculated that the consumption scale of China's PPS market is close to 200,000 tons. According to the current market price of PPS 60,000 tons / ton calculation, China's PPS output value of more than 10 billion yuan.